Monozukuri, a term that encapsulates the essence of Japanese manufacturing, is more than just a word; it represents a philosophy steeped in craftsmanship. The concept integrates a deep respect for the art of creating and the meticulous attention to detail that has become synonymous with Japan’s manufacturing prowess. From the production of world-renowned automobiles to traditional artisanal crafts, monozukuri serves as the backbone of Japan’s industrial landscape. This article embarks on a journey to explore the multifaceted world of monozukuri, its historical roots, guiding principles, and its profound impact on both local and global manufacturing practices.

Understanding Monozukuri: A Deep Dive into Japanese Craftsmanship

Monozukuri, literally translating to "making things," embodies a culture of craftsmanship that has evolved over centuries in Japan. It is a holistic approach that emphasizes not only the physical act of manufacturing but also the spirit of creation. Monozukuri signifies a commitment to quality, creativity, and efficiency, fostering an environment where artisans and engineers collaborate seamlessly. In this framework, the maker’s pride in their work is paramount, driving them to push the boundaries of innovation while adhering to traditional values.

At the heart of monozukuri lies a unique relationship between the artisan and the materials they use. Japanese craftsmen often engage deeply with their chosen materials, developing an intimate understanding that informs their techniques and enhances the final product. This engagement goes beyond mere functionalism; it incorporates aesthetic considerations and emotional resonance, creating products that are not only practical but also imbued with beauty and meaning.

Monozukuri also emphasizes process over product. The journey of creation is as significant as the finished item, and this focus fosters continuous improvement, known as "kaizen." This philosophy encourages artisans and manufacturers to consistently refine their methods, striving for excellence at every step. The result is a culture that values innovation without losing sight of tradition, a delicate balance that has become a hallmark of Japanese manufacturing.

The principles of monozukuri extend beyond individual crafts. They influence entire industries, affecting everything from supply chain management to customer engagement. This comprehensive view of manufacturing encourages companies to take responsibility for their entire production process, respecting the environment, their employees, and the communities they serve.

In essence, monozukuri is about creating more than just products; it is about crafting experiences and building relationships. As we delve deeper into its historical roots, we uncover the rich cultural tapestry that has shaped this unique approach to manufacturing and craftsmanship.

The Historical Roots of Monozukuri in Japanese Culture

To understand monozukuri fully, one must appreciate its historical context within Japanese culture. The roots of monozukuri can be traced back to ancient Japan, where the craft of making goods was intertwined with spiritual beliefs and social values. Early artisans viewed their work as an expression of devotion, often dedicating their creations to the kami, or spirits, that inhabit the natural world. This sacred relationship with craftsmanship established a deep respect for the materials and techniques used in production.

During the Edo period (1603-1868), there was a notable rise in specialized crafts, which contributed to the development of monozukuri. Artisans began to take pride in their specific trades, leading to a guild system that protected and promoted the skills of different crafts. This era saw the flourishing of unique regional specialties, from textiles to ceramics, each steeped in local traditions and techniques. The establishment of these guilds not only preserved traditional craftsmanship but also fostered a competitive spirit that pushed artisans towards continuous improvement.

Japan’s industrialization in the late 19th and early 20th centuries further transformed the landscape of monozukuri. The introduction of Western manufacturing techniques presented new challenges and opportunities for Japanese craftsmen. Rather than abandoning their traditions, many artisans integrated these new methods into their practices, resulting in a hybrid approach that married traditional craftsmanship with modern efficiency. This adaptation laid the groundwork for Japan’s emergence as a global manufacturing powerhouse in the decades that followed.

The devastation of World War II served as a catalyst for the revival of monozukuri. In the face of significant loss, Japanese manufacturers recognized the need to rebuild and innovate. The principles of monozukuri became central to this reconstruction, as companies sought to not only restore their industries but also to elevate their standards of quality and craftsmanship. This period marked the beginning of Japan’s reputation for producing high-quality goods, setting the stage for its dominance in various sectors.

Today, monozukuri remains a vital part of Japan’s cultural identity. It is celebrated in various forms, from traditional crafts to cutting-edge technology. By understanding its historical roots, we can appreciate the resilience and adaptability that have allowed monozukuri to thrive in an ever-evolving global landscape.

Key Principles of Monozukuri: Beyond Just Manufacturing

The principles of monozukuri extend far beyond the scope of traditional manufacturing. They encompass a holistic understanding of production that integrates quality, craftsmanship, and the human element into every aspect of the process. At its core, monozukuri emphasizes the importance of skill and knowledge, elevating the role of the artisan from mere laborer to a respected creator and innovator. This transformation is crucial, as it fosters an environment where individuals take personal pride in their work, leading to an overall enhancement of product quality.

One of the cornerstone principles of monozukuri is "monozukuri no kokoro," or the spirit of making things. This concept emphasizes the emotional connection between the maker and the product, encouraging artisans to pour their heart and soul into their creations. This heartfelt approach results in products that resonate with consumers on a deeper level, forging connections that go beyond function and price.

Another essential principle is the commitment to continuous improvement, or "kaizen." This philosophy advocates for incremental changes in processes and practices, promoting a culture of learning and adaptation. By regularly assessing and refining their techniques, artisans and manufacturers are not only enhancing quality but also fostering an environment where innovation is encouraged and celebrated. This relentless pursuit of excellence has allowed Japanese manufacturers to set unprecedented standards in various industries.

Monozukuri also places a strong emphasis on respect for materials and the environment. Artisans are taught to honor the resources they use, practicing sustainable methods and minimizing waste. This principle aligns with global trends towards sustainability and ethical production, showcasing how monozukuri can serve as a model for environmentally conscious manufacturing practices.

Moreover, collaboration plays a vital role in monozukuri. The integration of different crafts and skills is a hallmark of the process, creating a synergy that enhances the final product. This collaborative spirit allows for the blending of traditional and modern techniques, resulting in innovative solutions that address contemporary manufacturing challenges.

In sum, the principles of monozukuri reflect a comprehensive approach to manufacturing that values quality, sustainability, and collaboration. These elements not only shape the production of goods in Japan but also offer valuable lessons for manufacturers around the world.

How Monozukuri Shapes Product Quality and Innovation

The influence of monozukuri on product quality is profound and multifaceted. At its core, the philosophy advocates for an unwavering commitment to excellence, manifesting in meticulous attention to detail at every stage of the manufacturing process. From design to production, each step is approached with the utmost care, ensuring that the final product meets the highest standards. This dedication to quality is evident in the reputation that Japanese products have earned globally, often synonymous with reliability and durability.

Incorporating the principles of monozukuri into product development encourages innovation that is both practical and meaningful. Rather than simply following trends, Japanese manufacturers aim to create goods that genuinely enhance the user experience. This user-centric approach, rooted in a deep understanding of consumer needs, drives innovation that is not only functional but also emotionally resonant.

Moreover, the philosophy of continuous improvement, or kaizen, allows manufacturers to adapt rapidly to changing market demands and technological advancements. By assessing their processes regularly and seeking feedback, companies can identify areas for enhancement, leading to innovative solutions that address contemporary challenges. This dynamic response to change is critical in an era where consumer preferences shift rapidly.

Monozukuri also fosters a culture of collaboration among various stakeholders, from artisans to engineers to marketers. This collaborative approach not only enhances the creativity and innovation of product designs but also ensures that the craftsmanship behind each item is communicated effectively to the consumer. The synergy created through teamwork leads to products that reflect a balance of artistry and functionality.

Additionally, the emphasis on sustainability within monozukuri practices drives innovation towards environmentally friendly solutions. As awareness of environmental issues continues to grow, manufacturers are increasingly seeking ways to reduce their ecological footprint. By prioritizing sustainable materials and processes, Japanese manufacturers are leading the way in creating products that are both high-quality and environmentally responsible.

Ultimately, monozukuri shapes product quality and innovation in a way that is deeply ingrained in Japanese culture. By prioritizing craftsmanship, collaboration, and sustainability, this philosophy not only elevates the standard of goods produced in Japan but also sets a benchmark for manufacturers worldwide.

The Role of Tradition in Modern Japanese Manufacturing

Tradition plays a pivotal role in shaping modern Japanese manufacturing practices, intertwining with the principles of monozukuri to create a unique and effective production environment. While the world rapidly adopts new technologies and methodologies, Japan’s manufacturing sector continues to honor its rich heritage, integrating traditional techniques and values into contemporary practices. This fusion of old and new not only preserves cultural identity but also enhances the authenticity and quality of products.

The reverence for traditional craftsmanship is evident in various industries, from textiles to ceramics to automotive manufacturing. Many modern companies actively seek to incorporate traditional skills and techniques into their production processes, creating a sense of continuity that reflects Japan’s commitment to quality and artistry. This respect for tradition fosters a sense of pride among artisans and manufacturers, reinforcing the notion that they are part of a long lineage of skilled creators.

Furthermore, the preservation of traditional techniques often leads to innovations that enhance modern manufacturing. By revisiting age-old methods, companies can uncover unique approaches to problem-solving that might have been overlooked in contemporary practices. This ongoing dialogue between tradition and innovation creates a dynamic manufacturing landscape that prioritizes both heritage and progress.

However, the integration of tradition in modern manufacturing extends beyond physical techniques; it encompasses values such as discipline, dedication, and attention to detail. These principles, deeply rooted in Japan’s cultural history, continue to guide artisans and manufacturers today. The unwavering commitment to quality that characterizes monozukuri is a direct reflection of these traditional values, fostering an environment where excellence is the norm.

Moreover, as globalization transforms industries, the retention of traditional practices serves as a differentiating factor for Japanese products in the global marketplace. Consumers increasingly seek authentic, culturally rich products that tell a story. By embracing tradition, Japanese manufacturers create items that resonate with consumers on a deeper level, enhancing their appeal and marketability.

In conclusion, tradition is an integral component of modern Japanese manufacturing, influencing not only techniques but also the values and principles that guide production. This harmonious blend of heritage and contemporary practices is a hallmark of monozukuri, allowing the philosophy to thrive and adapt in an ever-changing global economy.

Monozukuri and Its Impact on Global Manufacturing Standards

The influence of monozukuri extends far beyond Japan’s borders, shaping global manufacturing standards and practices. With its unwavering commitment to quality, craftsmanship, and continuous improvement, monozukuri has become a benchmark for manufacturers around the world. The principles embedded within this philosophy resonate with many industries, prompting a reevaluation of traditional manufacturing methods and inspiring a shift towards greater efficiency and sustainability.

One of the most notable impacts of monozukuri on global standards is the emphasis on quality assurance. Companies worldwide have begun to adopt Japan’s rigorous quality control measures, recognizing that a commitment to excellence can set them apart in competitive markets. The principles of kaizen and continuous improvement have also gained traction, encouraging organizations to constantly evaluate their processes and implement incremental changes that lead to better outcomes.

In the automotive industry, for instance, the concept of lean manufacturing, which aims to minimize waste while maximizing value, draws heavily from monozukuri principles. Japanese automotive manufacturers, such as Toyota, have set the standard for efficient production techniques that prioritize quality and customer satisfaction. This approach has inspired global automotive companies to reevaluate their practices and implement similar strategies, leading to a wider acknowledgment of the importance of quality in manufacturing.

The cultural aspects of monozukuri, particularly the respect for craftsmanship and materials, have also found resonance in other countries. Manufacturers are increasingly recognizing the value of skilled labor and traditional techniques, leading to a resurgence of artisanal practices in various industries. This shift is a clear indication that the principles of monozukuri are being embraced globally, fostering a renewed appreciation for quality and craftsmanship.

Additionally, as sustainability becomes a central concern for consumers and manufacturers alike, the eco-friendly practices inherent in monozukuri are being adopted worldwide. The focus on minimizing waste and respecting materials aligns with global trends toward sustainable production, prompting companies to reevaluate their environmental impact. This collective shift towards responsible manufacturing is a testament to the enduring relevance of monozukuri in the modern world.

Ultimately, the impact of monozukuri on global manufacturing standards cannot be overstated. By promoting quality, efficiency, and sustainability, the principles of monozukuri serve as a guiding light for manufacturers worldwide, encouraging them to adopt practices that prioritize excellence and integrity in production.

Case Studies: Successful Monozukuri Practices in Japan

Examining specific case studies of successful monozukuri practices in Japan reveals how the philosophy has been effectively integrated into various industries, resulting in exceptional products and innovative processes. One such example is Toyota, a company synonymous with quality and efficiency. Toyota’s production system, known for its lean manufacturing principles, exemplifies monozukuri by emphasizing continuous improvement, teamwork, and a deep respect for craftsmanship. This system has not only revolutionized the automotive industry but has also influenced manufacturing practices globally.

Another notable case is that of Muji, a retail company that embodies the principles of minimalism and functionality. Muji’s approach to product design emphasizes simplicity, quality materials, and sustainable practices. By focusing on creating products that are both functional and aesthetically pleasing, Muji resonates with consumers seeking authenticity in their purchases. The company’s commitment to monozukuri principles has established it as a leader in the global market for household goods.

In the realm of traditional craftsmanship, the art of pottery in the town of Mashiko serves as a prime example of successful monozukuri practices. Renowned for its rich history of pottery-making, Mashiko has preserved traditional techniques while embracing modern innovations. Artisans in this region combine age-old methods with contemporary design, resulting in unique pottery that reflects both the past and the present. This harmonious blend of tradition and innovation is a testament to the enduring relevance of monozukuri in artisanal crafts.

The fashion industry also showcases successful monozukuri practices, particularly through brands like Issey Miyake and Comme des Garçons. These designers prioritize craftsmanship and innovation, often experimenting with materials and techniques that challenge conventional notions of fashion. Their commitment to quality and artistry not only elevates their brands but also influences global fashion trends, reinforcing the importance of monozukuri in creative industries.

Moreover, the Japanese electronics company Sony illustrates how monozukuri principles can drive innovation in technology. Sony’s commitment to quality, design, and consumer experience has led to groundbreaking products that redefine user interaction. By prioritizing craftsmanship and continuous improvement, Sony has maintained its position as a leader in the competitive electronics market.

Through these case studies, it is evident that monozukuri practices are not confined to traditional manufacturing; they permeate various industries, demonstrating their versatility and relevance. These examples highlight how the principles of monozukuri continue to inspire excellence and innovation in Japan’s manufacturing landscape.

The Human Element: Skilled Artisans and Their Craft

At the core of monozukuri lies the human element—the skilled artisans whose dedication and passion breathe life into the manufacturing process. These craftsmen and craftswomen play an integral role in ensuring that the principles of monozukuri are upheld, infusing their work with creativity, precision, and a deep respect for their materials. Their expertise not only shapes the quality of the products but also embodies the spirit of monozukuri itself.

The training and apprenticeship of skilled artisans in Japan often span years, emphasizing the importance of mentorship and the passing down of techniques from one generation to the next. This dedication to developing expertise fosters a profound connection between the artisan and their craft, as they continually refine their skills and deepen their understanding of their materials. This connection is integral to the philosophy of monozukuri, which values the emotional investment that artisans bring to their work.

In many traditional crafts, such as pottery or textile weaving, artisans often engage in a process of experimentation and exploration, seeking new ways to manipulate materials while respecting their inherent qualities. This creative exploration leads to unique products that reflect both individual artistry and the overarching principles of monozukuri. The emotional resonance of these handcrafted items often appeals to consumers seeking authenticity and connection with the maker.

Moreover, the role of artisans extends beyond mere production; they are also key contributors to innovation and improvement. By continually assessing and refining their techniques, artisans embody the spirit of kaizen, fostering a culture of continuous improvement that permeates the entire manufacturing process. This commitment to excellence drives manufacturers to seek new solutions and approaches, ultimately enhancing the quality and functionality of their products.

Despite the increasing automation and technological advancements in manufacturing, the human element remains irreplaceable in monozukuri. Artisans bring a unique perspective and a level of creativity that machines cannot replicate. Their intuition, artistry, and dedication add intrinsic value to the products they create, reinforcing the notion that craftsmanship is an art form.

In conclusion, the human element is central to the philosophy of monozukuri. Skilled artisans not only ensure the quality of products but also embody the spirit of craftsmanship that defines Japanese manufacturing. Their dedication to their craft, commitment to continuous improvement, and emotional investment create a manufacturing landscape that honors tradition while embracing innovation.

Technology Meets Tradition: The Future of Monozukuri

As Japan navigates a rapidly changing global landscape, the future of monozukuri lies at the intersection of technology and tradition. With advancements in automation, artificial intelligence, and digitalization transforming industries worldwide, Japanese manufacturers are faced with the challenge of integrating these technological innovations while preserving the core principles of monozukuri. This fusion of old and new presents exciting opportunities to enhance efficiency, quality, and creativity in production.

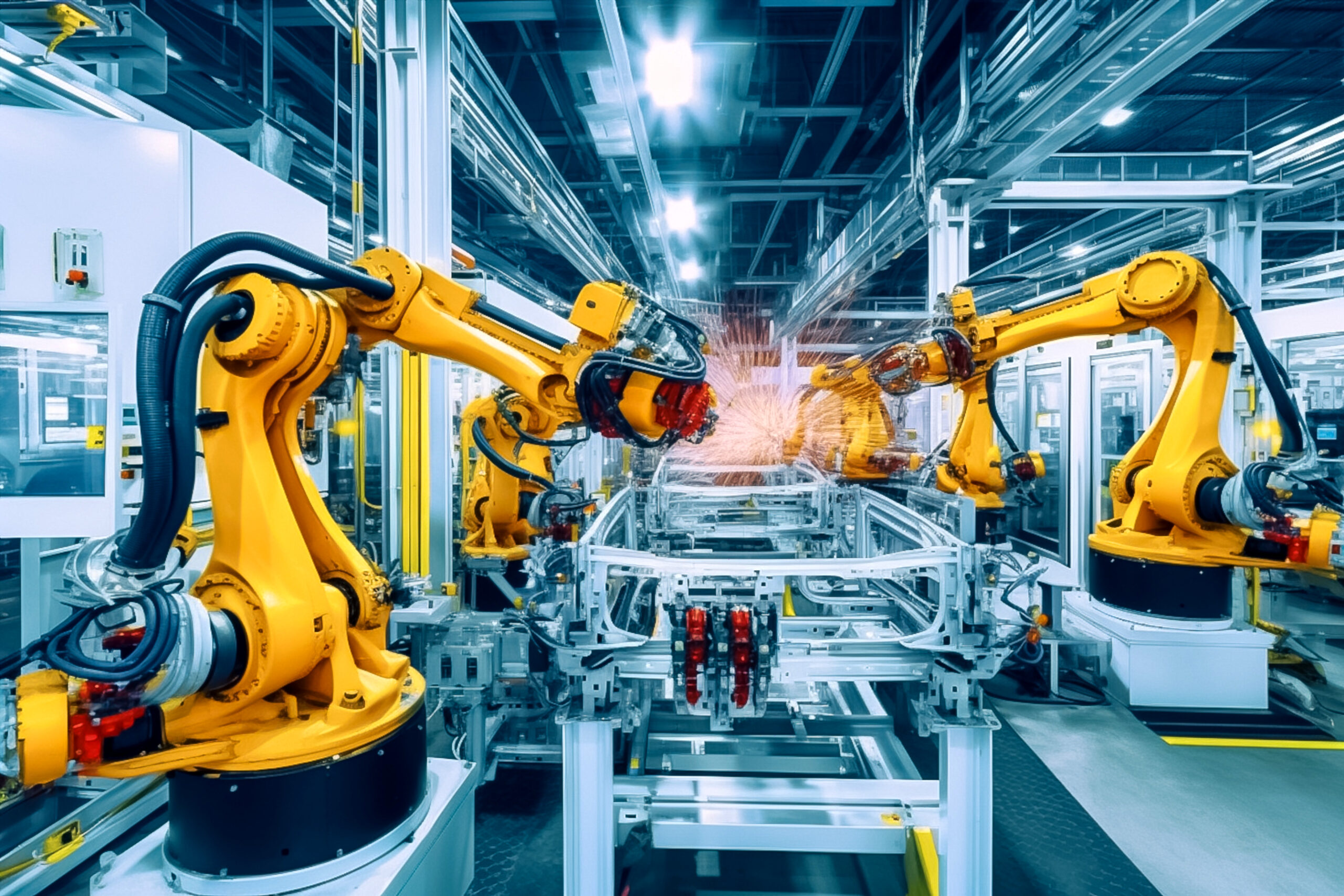

One notable trend is the use of advanced manufacturing technologies, such as robotics and 3D printing, which can complement traditional craftsmanship. These technologies streamline processes and reduce labor-intensive tasks, allowing artisans to focus on more intricate and creative aspects of their work. By leveraging technology in this way, manufacturers can enhance productivity while retaining the artisanal touch that defines monozukuri.

Furthermore, digital tools enable better collaboration and communication among teams, breaking down silos and fostering a culture of innovation. Platforms that support real-time feedback and project management empower artisans and engineers to work together more effectively, enhancing the quality of the final product. This collaborative approach not only improves efficiency but also reinforces the principles of monozukuri by valuing every individual’s contribution to the manufacturing process.

While technology presents numerous advantages, it is crucial for manufacturers to remain grounded in the traditional values of monozukuri. As automation becomes more prevalent, there is a risk of losing the craftsmanship and artistry that are hallmarks of Japanese manufacturing. To mitigate this risk, companies must cultivate a culture that honors traditional skills while embracing modern advancements. This balance will ensure that the essence of monozukuri is preserved for future generations.

Education and training initiatives will play a vital role in shaping the future of monozukuri. By equipping artisans with the skills to utilize new technologies while honing their traditional crafts, manufacturers can foster a new generation of skilled workers who embody the principles of monozukuri. This commitment to education is essential for maintaining Japan’s competitive edge in the global market.

In conclusion, the future of